Double Pitch & Straight Sidebar

Double Pitch Conveyor Series chains are ideally suited for light to medium duty material handling applications. These chains are similar to standard chain, except the plates are straight and the pitch is twice as long.

A2000- Drive Series

Double Pitch Conveyor Series chains are available in C2000 (standard roller) and C2002 (large roller) series. 1 1/2" pitch and larger chains utilize heavy stlye link pates (i.e. one size larger than standard chain). The chain number is found by adding 2,000 or 2002 to the standard chains and using the prefix "C". An "H" suffix is added to chains with heavy style link plates. For example, 60 double pitch conveyor series (1 1/2") is designed C2060H.

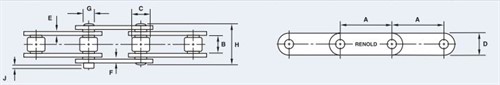

C2000- Conveyor Series Standard Roller

Rollers are the same diameter as the corresponding ANSI chain of 1/2 the pitch. Link plates are straight and unbeveled and the construction of the roller and pin link plates are identical to improve sliding wear properties.

C2002- Conveyor Series Large Roller

Identical to the C2000 series except that they possess large, oversized rollers which project above and below the link plates to produce a rolling rather than sliding action. Friction is thus minimized across the supporting surface to reduce wear and power requirements.

In general we recommend operating these chains over sprockets specially made for double pitch chains. However, standard ANSI sprockets can be used provided they have at least 30 teeth.

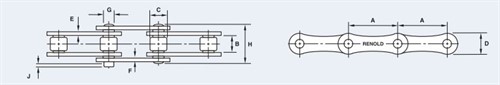

Double Pitch Roller Chain Dimensions

| Chain No. | Pitch inch |

Inside Width Min |

Roller diam Max |

Plate Height Max |

Inner Plate Thickness Max |

Outer Plate Thickness Max |

Pin Diam Max |

Pin Length Max |

Conn Link Extension Max |

Tensile Strength Min |

Rated Working Load | Mass |

| A | B | C | D | E | F | G | H1 | J | Lbs | Lbs/Ft | ||

| A2040 | 1.000 | 0.309 | 0.312 | 0.465 | 0.059 | 0.059 | 0.156 | 0.701 | 0.154 | 3,125 | 600 | 0.27 |

| A2050 | 1.250 | 0.370 | 0.400 | 0.591 | 0.079 | 0.079 | 0.200 | 0.859 | 0.162 | 4,880 | 950 | 0.47 |

| A2060 | 1.500 | 0.495 | 0.469 | 0.701 | 0.094 | 0.094 | 0.235 | 1.060 | 0.181 | 7,030 | 1,200 | 0.70 |

| A2080 | 2.000 | 0.620 | 0.625 | 0.950 | 1.128 | 1.128 | 0.313 | 1.320 | 0.213 | 12,500 | 2,000 | 1.18 |

| C2040 | 1.000 | 0.309 | 0.312 | 0.465 | 0.059 | 0.059 | 0.156 | 0.701 | 0.154 | 3,125 | 810 | 0.34 |

| C2050 | 1.250 | 0.370 | 0.400 | 0.591 | 0.079 | 0.079 | 0.200 | 0.859 | 0.162 | 4,880 | 1,400 | 0.56 |

| C2060H | 1.500 | 0.495 | 0.469 | 0.701 | 0.094 | 0.094 | 0.235 | 1.127 | 0.181 | 7,030 | 2,200 | 0.96 |

| C2080H | 2.000 | 0.620 | 0.625 | 0.950 | 1.128 | 1.128 | 0.313 | 1.411 | 0.213 | 12,500 | 3,600 | 1.62 |

| C2100H | 2.500 | 0.748 | 0.750 | 1.135 | 0.189 | 0.189 | 0.376 | 1.671 | 0.169 | 19,530 | 5,500 | 2.32 |

| C2120H | 3.000 | 1.000 | 0.875 | 1.383 | 0.221 | 0.221 | 0.437 | 2.065 | 0.209 | 28,125 | 7,300 | 3.30 |

| C2160H | 4.000 | 1.240 | 1.125 | 1.887 | 0.287 | 0.287 | 0.563 | 2.585 | 0.264 | 50,000 | 12,600 | 5.36 |

| C2042 | 1.000 | 0.309 | 0.625 | 0.465 | 0.059 | 0.059 | 0.156 | 0.701 | 0.154 | 3,125 | 810 | 0.55 |

| C2052 | 1.250 | 0.370 | 0.750 | 0.591 | 0.079 | 0.079 | 0.200 | 0.859 | 0.162 | 4,880 | 1,400 | 0.84 |

| C2062H | 1.500 | 0.495 | 0.875 | 0.701 | 0.094 | 0.094 | 0.235 | 1.127 | 0.181 | 7,030 | 2,200 | 1.36 |

| C2082H | 2.000 | 0.620 | 1.125 | 0.950 | 1.128 | 1.128 | 0.313 | 1.411 | 0.213 | 12,500 | 3,600 | 2.25 |

| C2102H | 2.500 | 0.748 | 1.562 | 1.135 | 0.189 | 0.189 | 0.376 | 1.671 | 0.169 | 19,530 | 5,500 | 3.79 |

| C2122H | 3.000 | 1.000 | 1.750 | 1.383 | 0.221 | 0.221 | 0.437 | 2.065 | 0.209 | 28,125 | 7,300 | 5.29 |

| C2162H | 4.000 | 1.240 | 2.250 | 1.887 | 0.287 | 0.287 | 0.563 | 2.585 | 0.264 | 50,000 | 12,600 | 8.58 |