Blue

Renold’s unique control over pin / bush contact makes sure that wear life exceeds other brands. Little initial chain adjustment is therefore required.

Renold roller chain is highly fatigue resistant, giving up to four times the life of other leading competitor chains. Breaking loads exceed the minimum requirements of international standards.

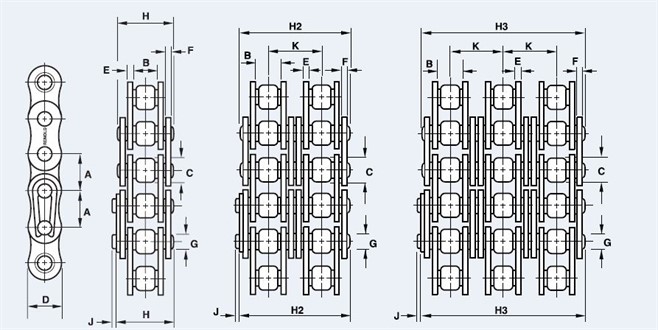

- Sizes range from 4 mm to 4 inch pitch

- Can be ordered to European (BS) and ANSI Standard in simplex, duplex, triplex and multiplex configurations

- Solid roller and solid bush

- End-softened pins make it easy to disassemble this chain

- Look for the round or "spin" riveting for the sign of a Renold chain

- The high waist plate shape with a high waist gives better stress distribution

- Engineered for the best fatigue resistance you can get

- Delivers wear resistance that surpasses anything produced elsewhere

- Components manufactured to the highest specifications for unbeatable accuracy

Key Product Features

- Solid roller, solid bush

- End-softened pins for easy disassembly

- High waist plate shape

- Unrivalled component accuracy

- Reliability, Reputation and Performance

Fatigue life is substantially improved by optimising fits between pin, bush and plates and controlling plate hole quality. Sprocket life is enhanced by matching the chain gearing exactly to the tooth form.

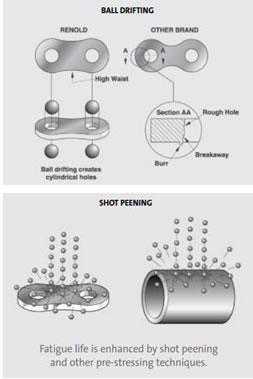

Renold pioneered ball drifting to create precisely controlled holes, which combined with other Renold process technology reinforces fatigue resistance and improves the wear performance of the chain. Fatigue life is further enhanced by shot peening and other pre-stressing processes.

Renold pioneered ball drifting to create precisely controlled holes, which combined with other Renold process technology reinforces fatigue resistance and improves the wear performance of the chain. Fatigue life is further enhanced by shot peening and other pre-stressing processes.

Specially formulated lubricants reduce initial wear, give corrosion protection and ensure long storage life. Renold pins are case-hardened and centreless ground producing perfectly cylindrical diameters with extremely high surface hardness. Component life is maximised by the expert use and control of heat treatment during the manufacturing process.

What this means to you:

- Unbeatable wear and fatigue resistance

- Longer working life

- Reduced bedding-in times

- Better resistance to shock loadings

- The end-softened pin and a spin rivet to make cutting easy

Technical Data

Renold Roller Chain No. 25, 35, 41

| Chain No. | Pitch inch | Inside Width Min |

Roller diam Max |

Plate Height Max |

Inner Plate Thickness Max |

Outer Plate Thickness Max |

Pin Diam Max |

Pin Length Max |

Conn Link Extension Max |

Transverse Pitch Nom |

Tensile Strength Min |

Mass |

| A | B | C | D | E | F | G | H1 | J | K | Lbs | Lbs/Ft | |

| 25 | 0.250 | 0.122 | 0.130 | 0.237 | 0.030 | 0.030 | 0.091 | 0.359 | 0.031 | 780 | 0.09 | |

| 25-2 | 0.250 | 0.122 | 0.130 | 0.237 | 0.030 | 0.030 | 0.091 | 0.611 | 0.031 | 0.252 | 1,560 | 0.17 |

| 25-3 | 0.250 | 0.122 | 0.130 | 0.237 | 0.030 | 0.030 | 0.091 | 0.859 | 0.031 | 0.252 | 2,340 | 0.26 |

| 35 | 0.375 | 0.184 | 0.200 | 0.356 | 0.049 | 0.049 | 0.141 | 0.473 | 0.043 | 1,760 | 0.23 | |

| 35-2 | 0.375 | 0.184 | 0.200 | 0.356 | 0.049 | 0.049 | 0.141 | 0.875 | 0.043 | 0.399 | 3,520 | 0.47 |

| 35-3 | 0.375 | 0.184 | 0.200 | 0.356 | 0.049 | 0.049 | 0.141 | 1.269 | 0.043 | 0.399 | 5,280 | 0.70 |

| 35-4 | 0.375 | 0.184 | 0.200 | 0.356 | 0.049 | 0.049 | 0.141 | 1.665 | 0.043 | 0.399 | 7,040 | 0.82 |

| 35-5 | 0.375 | 0.184 | 0.200 | 0.356 | 0.049 | 0.049 | 0.141 | 2.063 | 0.043 | 0.399 | 8,800 | 1.05 |

| 35-6 | 0.375 | 0.184 | 0.200 | 0.356 | 0.049 | 0.049 | 0.141 | 2.462 | 0.043 | 0.399 | 10,560 | 1.27 |

| 41 | 0.500 | 0.246 | 0.306 | 0.390 | 0.050 | 0.050 | 0.141 | 0.571 | 0.055 | 1,500 | 0.28 |

Renold Roller Chain No. 40, 50, 60, 80

| Chain No. | Pitch inch | Inside Width Min |

Roller diam Max |

Plate Height Max |

Inner Plate Thickness Max |

Outer Plate Thickness Max |

Pin Diam Max |

Pin Length Max |

Conn Link Extension Max |

Transverse Pitch Nom |

Tensile Strength Min |

Mass |

| A | B | C | D | E | F | G | H1 | J | K | Lbs | Lbs/Ft | |

| 40 | 0.500 | 0.309 | 0.312 | 0.475 | 0.061 | 0.061 | 0.156 | 0.646 | 0.055 | 3,125 | 0.40 | |

| 40-2 | 0.500 | 0.309 | 0.312 | 0.475 | 0.061 | 0.061 | 0.156 | 1.214 | 0.055 | 0.566 | 6,250 | 0.80 |

| 40-3 | 0.500 | 0.309 | 0.312 | 0.475 | 0.061 | 0.061 | 0.156 | 1.777 | 0.055 | 0.566 | 9,375 | 1.21 |

| 40-4 | 0.500 | 0.309 | 0.312 | 0.475 | 0.061 | 0.061 | 0.156 | 2.364 | 0.055 | 0.566 | 12,500 | 1.65 |

| 40-5 | 0.500 | 0.309 | 0.312 | 0.475 | 0.061 | 0.061 | 0.156 | 2.938 | 0.055 | 0.566 | 15,625 | 2.10 |

| 40-6 | 0.500 | 0.309 | 0.312 | 0.475 | 0.061 | 0.061 | 0.156 | 3.505 | 0.055 | 0.566 | 18,750 | 2.53 |

| 50 | 0.625 | 0.370 | 0.400 | 0.594 | 0.080 | 0.080 | 0.200 | 0.804 | 0.043 | 4,880 | 0.67 | |

| 50-2 | 0.625 | 0.370 | 0.400 | 0.594 | 0.080 | 0.080 | 0.200 | 1.513 | 0.043 | 0.713 | 9,760 | 1.34 |

| 50-3 | 0.625 | 0.370 | 0.400 | 0.594 | 0.080 | 0.080 | 0.200 | 2.226 | 0.043 | 0.713 | 14,640 | 2.01 |

| 50-4 | 0.625 | 0.370 | 0.400 | 0.594 | 0.080 | 0.080 | 0.200 | 2.963 | 0.043 | 0.713 | 19,520 | 2.68 |

| 50-5 | 0.625 | 0.370 | 0.400 | 0.594 | 0.080 | 0.080 | 0.200 | 3.672 | 0.043 | 0.713 | 24,400 | 3.35 |

| 50-6 | 0.625 | 0.370 | 0.400 | 0.595 | 0.080 | 0.080 | 0.200 | 4.385 | 0.043 | 0.713 | 29,280 | 4.02 |

| 60 | 0.750 | 0.495 | 0.469 | 0.713 | 0.094 | 0.094 | 0.235 | 0.997 | 0.043 | 7,030 | 0.98 | |

| 60-2 | 0.750 | 0.495 | 0.469 | 0.713 | 0.094 | 0.094 | 0.235 | 1.895 | 0.043 | 0.897 | 14,060 | 1.98 |

| 60-3 | 0.750 | 0.495 | 0.469 | 0.713 | 0.094 | 0.094 | 0.235 | 2.793 | 0.043 | 0.897 | 21,090 | 2.97 |

| 60-4 | 0.750 | 0.495 | 0.469 | 0.713 | 0.094 | 0.094 | 0.235 | 3.719 | 0.043 | 0.897 | 28,120 | 3.97 |

| 60-5 | 0.750 | 0.495 | 0.469 | 0.713 | 0.094 | 0.094 | 0.235 | 4.606 | 0.043 | 0.897 | 35,150 | 4.96 |

| 60-6 | 0.750 | 0.495 | 0.469 | 0.713 | 0.094 | 0.094 | 0.235 | 5.524 | 0.043 | 0.897 | 42,180 | 5.80 |

| 80 | 1.000 | 0.620 | 0.625 | 0.950 | 0.128 | 0.128 | 0.313 | 1.288 | 0.118 | 12,500 | 1.88 | |

| 80-2 | 1.000 | 0.620 | 0.625 | 0.950 | 0.128 | 0.128 | 0.313 | 2.439 | 0.118 | 1.153 | 25,000 | 3.69 |

| 80-3 | 1.000 | 0.620 | 0.625 | 0.950 | 0.128 | 0.128 | 0.313 | 3.593 | 0.118 | 1.153 | 37,500 | 5.56 |

| 80-4 | 1.000 | 0.620 | 0.625 | 0.950 | 0.128 | 0.128 | 0.313 | 4.756 | 0.118 | 1.153 | 50,000 | 7.50 |

| 80-5 | 1.000 | 0.620 | 0.625 | 0.950 | 0.128 | 0.128 | 0.313 | 5.906 | 0.118 | 1.153 | 62,500 | 9.38 |

| 80-6 | 1.000 | 0.620 | 0.625 | 0.950 | 0.128 | 0.128 | 0.313 | 7.068 | 0.118 | 1.153 | 75,000 | 11.26 |

Renold Roller Chain No. 100, 120, 140, 160

| Chain No. | Pitch inch | Inside Width Min |

Roller diam Max |

Plate Height Max |

Inner Plate Thickness Max |

Outer Plate Thickness Max |

Pin Diam Max |

Pin Length Max |

Conn Link Extension Max |

Transverse Pitch Nom |

Tensile Strength Min |

Mass |

| A | B | C | D | E | F | G | H1 | J | K | Lbs | Lbs/Ft | |

| 100 | 1.250 | 0.744 | 0.750 | 1.188 | 0.160 | 0.160 | 0.376 | 1.564 | 0.165 | 19,530 | 2.81 | |

| 100-2 | 1.250 | 0.744 | 0.750 | 1.188 | 0.160 | 0.160 | 0.376 | 2.971 | 0.165 | 1.408 | 39,060 | 5.63 |

| 100-3 | 1.250 | 0.744 | 0.750 | 1.188 | 0.160 | 0.160 | 0.376 | 4.381 | 0.165 | 1.408 | 58,590 | 8.44 |

| 100-4 | 1.250 | 0.744 | 0.750 | 1.188 | 0.160 | 0.160 | 0.376 | 5.796 | 0.165 | 1.408 | 78,120 | 11.26 |

| 100-5 | 1.250 | 0.744 | 0.750 | 1.188 | 0.160 | 0.160 | 0.376 | 7.206 | 0.165 | 1.408 | 97,650 | 14.07 |

| 100-6 | 1.250 | 0.744 | 0.750 | 1.188 | 0.160 | 0.160 | 0.376 | 8.617 | 0.165 | 1.408 | 117,180 | 16.88 |

| 120 | 1.500 | 0.993 | 0.875 | 1.425 | 0.189 | 0.189 | 0.437 | 1.942 | 0.209 | 28,125 | 3.82 | |

| 120-2 | 1.500 | 0.993 | 0.875 | 1.425 | 0.189 | 0.189 | 0.437 | 3.731 | 0.209 | 1.789 | 56,250 | 7.37 |

| 120-3 | 1.500 | 0.993 | 0.875 | 1.425 | 0.189 | 0.189 | 0.437 | 5.524 | 0.209 | 1.789 | 84,375 | 11.19 |

| 120-4 | 1.500 | 0.993 | 0.875 | 1.425 | 0.189 | 0.189 | 0.437 | 7.317 | 0.209 | 1.789 | 112,500 | 15.28 |

| 120-5 | 1.500 | 0.993 | 0.875 | 1.425 | 0.189 | 0.189 | 0.437 | 9.109 | 0.209 | 1.789 | 140,625 | 18.36 |

| 120-6 | 1.500 | 0.993 | 0.875 | 1.425 | 0.189 | 0.189 | 0.437 | 10.898 | 0.209 | 1.789 | 168,750 | 22.45 |

| 140 | 1.750 | 0.993 | 1.000 | 1.663 | 0.221 | 0.211 | 0.500 | 2.084 | 0.205 | 38,280 | 5.23 | |

| 140-2 | 1.750 | 0.993 | 1.000 | 1.663 | 0.221 | 0.221 | 0.500 | 4.011 | 0.205 | 1.924 | 76,560 | 10.39 |

| 140-3 | 1.750 | 0.993 | 1.000 | 1.663 | 0.221 | 0.221 | 0.500 | 5.938 | 0.205 | 1.924 | 114,840 | 15.48 |

| 140-4 | 1.750 | 0.993 | 1.000 | 1.663 | 0.221 | 0.221 | 0.500 | 7.868 | 0.205 | 1.924 | 153,120 | 20.64 |

| 140-5 | 1.750 | 0.993 | 1.000 | 1.663 | 0.221 | 0.221 | 0.500 | 9.799 | 0.205 | 1.924 | 191,400 | 25.53 |

| 140-6 | 1.750 | 0.993 | 1.000 | 1.663 | 0.221 | 0.221 | 0.500 | 11.722 | 0.205 | 1.924 | 229,680 | 30.31 |

| 160 | 2.000 | 1.242 | 1.125 | 1.900 | 0.250 | 0.250 | 0.563 | 2.486 | 0.256 | 50,000 | 6.97 | |

| 160-2 | 2.000 | 1.242 | 1.125 | 1.900 | 0.250 | 0.250 | 0.563 | 4.791 | 0.256 | 2.305 | 100,000 | 13.80 |

| 160-3 | 2.000 | 1.242 | 1.125 | 1.900 | 0.250 | 0.250 | 0.563 | 7.100 | 0.256 | 2.305 | 150,000 | 20.77 |

| 160-4 | 2.000 | 1.242 | 1.125 | 1.900 | 0.250 | 0.250 | 0.563 | 9.409 | 0.256 | 2.305 | 200,000 | 27.60 |

| 160-5 | 2.000 | 1.242 | 1.125 | 1.900 | 0.250 | 0.250 | 0.563 | 11.710 | 0.256 | 2.305 | 250,000 | 34.64 |

| 160-6 | 2.000 | 1.242 | 1.125 | 1.900 | 0.250 | 0.250 | 0.563 | 14.015 | 0.256 | 2.305 | 300,000 | 41.54 |

Renold Roller Chain No. 180, 200, 240

| Chain No. | Pitch inch | Inside Width Min |

Roller diam Max |

Plate Height Max |

Inner Plate Thickness Max |

Outer Plate Thickness Max |

Pin Diam Max |

Pin Length Max |

Conn Link Extension Max |

Transverse Pitch Nom |

Tensile Strength Min |

Mass |

| A | B | C | D | E | F | G | H1 | J | K | Lbs | Lbs/Ft | |

| 180 | 2.250 | 1.397 | 1.406 | 2.139 | 0.281 | 0.281 | 0.688 | 2.782 | 0.311 | 63,280 | 9.34 | |

| 180-2 | 2.250 | 1.397 | 1.406 | 2.139 | 0.281 | 0.281 | 0.688 | 5.378 | 0.311 | 2.592 | 126,560 | 18.57 |

| 180-3 | 2.250 | 1.397 | 1.406 | 2.139 | 0.281 | 0.281 | 0.688 | 7.971 | 0.311 | 2.592 | 189,840 | 27.81 |

| 180-4 | 2.250 | 1.397 | 1.406 | 2.139 | 0.281 | 0.281 | 0.688 | 10.563 | 0.311 | 2.592 | 253,120 | 37.05 |

| 180-5 | 2.250 | 1.397 | 1.406 | 2.139 | 0.281 | 0.281 | 0.688 | 13.156 | 0.311 | 2.592 | 316,400 | 46.36 |

| 180-6 | 2.250 | 1.397 | 1.406 | 2.139 | 0.281 | 0.281 | 0.688 | 15.748 | 0.311 | 2.592 | 379,680 | 55.61 |

| 200 | 2.500 | 1.490 | 1.562 | 2.377 | 0.320 | 0.320 | 0.782 | 3.030 | 0.355 | 78,125 | 11.59 | |

| 200-2 | 2.500 | 1.490 | 1.562 | 2.377 | 0.320 | 0.320 | 0.782 | 5.851 | 0.355 | 2.817 | 156,250 | 23.05 |

| 200-3 | 2.500 | 1.490 | 1.562 | 2.377 | 0.320 | 0.320 | 0.782 | 9.023 | 0.355 | 2.817 | 234,375 | 34.30 |

| 200-4 | 2.500 | 1.490 | 1.562 | 2.377 | 0.320 | 0.320 | 0.782 | 11.489 | 0.355 | 2.817 | 312,500 | 46.10 |

| 200-5 | 2.500 | 1.490 | 1.562 | 2.377 | 0.320 | 0.320 | 0.782 | 13.955 | 0.355 | 2.817 | 390,625 | 57.15 |

| 200-6 | 2.500 | 1.490 | 1.562 | 2.377 | 0.320 | 0.320 | 0.782 | 16.422 | 0.355 | 2.817 | 468,750 | 68.61 |

| 240 | 3.000 | 1.864 | 1.875 | 2.852 | 0.375 | 0.375 | 0.938 | 3.719 | 0.414 | 112,500 | 16.75 | |

| 240-2 | 3.000 | 1.864 | 1.875 | 2.852 | 0.375 | 0.375 | 0.938 | 7.179 | 0.414 | 3.458 | 225,000 | 33.50 |

| 240-3 | 3.000 | 1.864 | 1.875 | 2.852 | 0.375 | 0.375 | 0.938 | 10.642 | 0.414 | 3.458 | 337,500 | 50.25 |

| 240-4 | 3.000 | 1.864 | 1.875 | 2.852 | 0.375 | 0.375 | 0.938 | 14.101 | 0.414 | 3.458 | 450,000 | 67.00 |

| 240-5 | 3.000 | 1.864 | 1.875 | 2.852 | 0.375 | 0.375 | 0.938 | 17.561 | 0.414 | 3.458 | 562,500 | 83.75 |

| 240-6 | 3.000 | 1.864 | 1.875 | 2.852 | 0.375 | 0.375 | 0.938 | 21.020 | 0.414 | 3.458 | 675,000 | 100.50 |