Welded Steel Mill Chain

Renold Jeffrey Welded Steel Mill Chains for the forestry and paper industries are built to move materials in demanding conditions. Equipment such as log decks and debarking drums can cause excessive wear on pin and sidebar edges.

Renold Jeffrey uses a perfected heat treatment process that gives our chains the strength, wear life and dimensional accuracy to withstand severe impact and abrasion from wood chips, ash and sawdust.

- Heat-treated pins are available as standard for greater strength and wear life in the toughest applications.

- Pins are press fit to sidebars to eliminate pin hole wear:

- Accurate pin-hole punches and machine-welded barrels ensure high quality and dimensional control.

Renold Jeffrey Welded Steel Mill Chains also allow greater operational flexibility than conventional cast chains. Offset sidebars and precision-welded barrels accommodate a wide variety of specialty attachments for use in nearly any application in which cast chains are used. Contact Renold Jeffrey for rugged Welded Steel Chains designed to excel in forestry, paper mill and saw mill applications.

Welded Steel Mill Chain

| Engineering Class Welded Steel Mill Chain | ||||||||||

| Chain No. | Pitch | Inner Width Max | Barrel Diam Max | Plate Height Max | Plate Thick Max | Pin Diam Max | Pin Length Max | Average Ultimate strength | Rated Working Load | Weight |

| A | B | C | D | E/F | G | H | Lbs | Lbs | Lbs/Ft | |

| WH78 | 2.609 | 1.500 | 0.875 | 1.125 | 0.250 | 0.500 | 3.000 | 30,000 | 3,500 | 3.90 |

| WH82 | 3.075 | 1.750 | 1.219 | 1.250 | 0.250 | 0.563 | 3.219 | 35,000 | 4,400 | 5.50 |

| WH784 | 4.000 | 1.500 | 0.875 | 1.125 | 0.250 | 0.500 | 2.953 | 30,000 | 3,500 | 3.30 |

| WH124 | 4.000 | 2.060 | 1.438 | 1.500 | 0.375 | 0.750 | 4.220 | 60,000 | 7,350 | 8.50 |

| WHX124HD | 4.063 | 2.000 | 1.625 | 2.000 | 0.500 | 0.875 | 4.672 | 90,000 | 9,150 | 14.40 |

| WH111 | 4.760 | 2.625 | 1.438 | 1.500 | 0.375 | 0.750 | 4.750 | 58,600 | 8,850 | 8.40 |

| WH106 | 6.000 | 2.063 | 1.375 | 1.500 | 0.375 | 0.750 | 4.187 | 56,500 | 7,400 | 6.70 |

| WH110 | 6.000 | 2.250 | 1.250 | 1.500 | 0.375 | 0.750 | 4.375 | 60,000 | 7,850 | 6.60 |

| WH132 | 6.050 | 3.375 | 1.750 | 2.000 | 0.500 | 1.000 | 6.172 | 100,000 | 13,100 | 13.50 |

| WHX132 | 15,300 | |||||||||

| WH150 | 6.050 | 3.375 | 1.750 | 2.500 | 0.500 | 1.000 | 6.172 | 100,000 | 13,100 | 14.50 |

| WHX150 | 14,500 | |||||||||

| WH155 | 6.050 | 3.313 | 1.750 | 2.500 | 0.563 | 1.125 | 6.563 | 175,000 | 17,000 | 20.50 |

| WH157 | 3.375 | 0.625 | 6.875 | 20,000 | ||||||

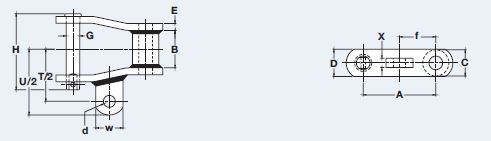

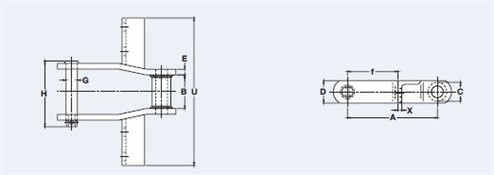

A-42 Welded Steel Mill Chain Attachment

| A-42 Welded Steel Mill Chain Attachments | |||||||||||||

| Chain No. | A | B | C | D | E | G | H | T/2 | U/2 | X | d | f | w |

| WH78 | 2.609 | 1.125 | 0.875 | 1.125 | 0.250 | 0.500 | 3.000 | 2.250 | 2.875 | 0.500 | 0.656 | 1.438 | 1.500 |

| WH82 | 3.075 | 1.250 | 1.219 | 1.250 | 0.250 | 0.563 | 3.219 | 2.500 | 3.125 | 0.375 | 0.563 | 1.531 | 1.500 |

| WH124 | 4.000 | 1.625 | 1.438 | 1.500 | 0.375 | 0.750 | 4.188 | 2.875 | 3.625 | 0.500 | 0.656 | 2.000 | 1.500 |

| WH1 10 | 6.000 | 1.875 | 1.250 | 1.500 | 0.375 | 0.750 | 4.375 | 2.563 | 3.141 | 0.406 | 0.500 | 2.250 | 1.500 |

| WH150 | 6.050 | 2.875 | 1.750 | 2.500 | 0.500 | 1.000 | 6.172 | 4.000 | 4.938 | 0.500 | 0.656 | 2.656 | 2.000 |

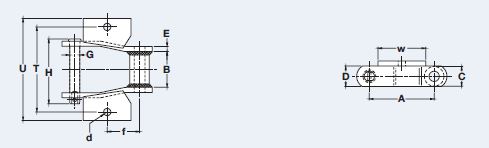

K-1 Welded Steel Mill Chain Attachment

| K-1 Welded Steel Mill Chain Attachments | ||||||||||||

| Chain No. | A | B | C | D | E | G | H | T | u | d | f | w |

| WH78 | 2.609 | 1.125 | 0.875 | 1.125 | 0.250 | 0.500 | 3.000 | 4.000 | 5.000 | 0.375 | 1.344 | 2.000 |

| WH82 | 3.075 | 1.250 | 1.219 | 1.250 | 0.250 | 0.563 | 3.219 | 4.250 | 5.500 | 0.375 | 1.578 | 1.750 |

| WH124 | 4.000 | 1.625 | 1.438 | 1.500 | 0.375 | 0.750 | 4.188 | 5.250 | 6.375 | 0.625 | 2.188 | 2.000 |

| WH150 | 6.050 | 2.875 | 1.750 | 2.500 | 0.500 | 1.000 | 6.172 | 7.500 | 9.125 | 0.562 | 2.656 | 4.000 |

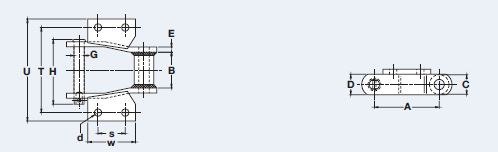

K-2 Welded Steel Mill Chain Attachment

| K-2 Welded Steel Mill Chain Attachments | ||||||||||||

| Chain No. | A | B | C | D | E | G | H | T | U | d | s | w |

| WH78 | 2.609 | 1.125 | 0.875 | 1.125 | 0.250 | 0.500 | 3.000 | 4.000 | 5.000 | 0.375 | 1.125 | 2.000 |

| WH82 | 3.075 | 1.250 | 1.219 | 1.250 | 0.250 | 0.563 | 3.219 | 4.250 | 5.500 | 0.375 | 1.313 | 2.875 |

| WH124 | 4.000 | 1.625 | 1.438 | 1.500 | 0.375 | 0.750 | 4.188 | 5.250 | 6.375 | 0.375 | 1.938 | 3.000 |

| WH111 | 4.760 | 2.250 | 1.438 | 1.500 | 0.375 | 0.750 | 4.750 | 6.250 | 7.500 | 0.500 | 2.313 | 3.500 |

| WH110 | 6.000 | 1.875 | 1.250 | 1.500 | 0.375 | 0.750 | 4.375 | 5.313 | 7.188 | 0.375 | 1.750 | 3.250 |

| WH132 | 6.050 | 2.875 | 1.750 | 2.000 | 0.500 | 1.000 | 6.172 | 7.500 | 9.125 | 0.500 | 2.750 | 4.000 |

| WH150 | 6.050 | 2.875 | 1.750 | 2.500 | 0.500 | 1.000 | 6.172 | 7.500 | 9.125 | 0.531 | 2.750 | 4.000 |

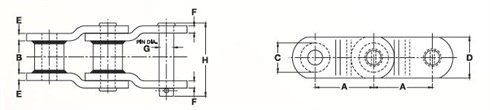

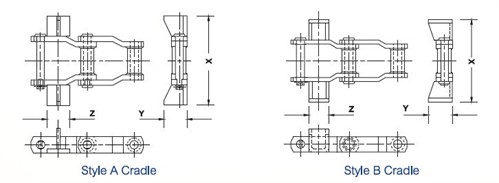

Welded Steel Mill Chain Wing / Cradle Attachment

| Welded Steel Mill Chain Wing / Cradle Attachments | ||||||||||||

| Chain No. | A | B | C | D | E | G | H | U | X | f | y | z |

| WH78 | 2.609 | 1.125 | 0.875 | 1.125 | 0.250 | 0.500 | 3.000 | 6.000 | 0.250 | 0.750 | - | - |

| WH82 | 3.075 | 1.250 | 1.219 | 1.250 | 0.250 | 0.563 | 3.219 | 6.500 | 0.250 | 0.750 | - | - |

| WH124 | 4.000 | 1.625 | 1.438 | 1.500 | 0.375 | 0.750 | 4.188 | 8.500 | 0.250 | 1.188 | 3.500 | 2.000 |

| WH132 | 6.050 | 2.875 | 1.750 | 2.000 | 0.500 | 1.000 | 6.172 | 12.375 | 0.500 | 1.500 | 3.000 | 2.500 |