Sugar Mill Chain

Moving sugar cane from harvest through pocessing requires top-quality chains that can stand up to abrasion, corrosion and high shock loads at ever increasing production rates.

Renold Jeffrey has been making high-quality engineering chain for more than 130 years. We understand the importance of quality, reliability and consistency to keep your sugar mill running at peak capacity.

Time matters during harvest. Count on Renold Jeffrey to move product from field to market, fast. Our chains are manufactured to the highest standards to deliver value in the most demanding applications.

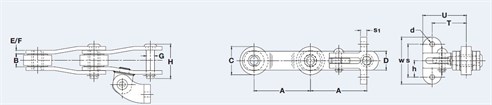

A-42 & C-Type Sugar Mill Chain

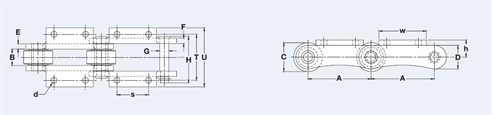

K-2 Type Sugar Mill Chain

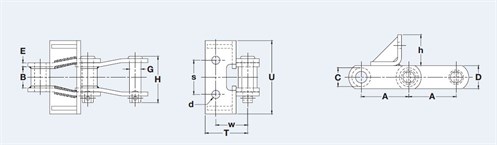

Welded Steel Type Sugar Mill Chain

| Sugar Mill Chain | |||||||||||||||||

| Chain No. | Att. Type | Pitch | Inner Width Max | Roller Diam Max | Plate Height Max | Plate Thick Max | Pin Diam Max | Pin Length Max | Average Ultimate Strength | Rated Working Load | |||||||

| A | B | C | D | E/F | G | H | T | U | d | h | s | s1 | w | Lbs | Lbs | ||

| 2113 | A-42 & 5CH | 4.040 | 1.313 | 2.000 | 1.500 | 0.313 | 0.687 | 3.125 | 3.188 | 4.188 | 0.531 | 1.375 | 2.750 | 0.375 | 4.750 | 29,000 | 4,700 |

| 2184P | A-42 & 2CH | 6.000 | 1.375 | 3.000 | 2.000 | 0.375 | 0.875 | 3.625 | 3.625 | 4.625 | 0.531 | 1.750 | 3.500 | 0.688 | 5.000 | 55,000 | 6,500 |

| 2184AC | A-42 & 2CH | 6.000 | 1.375 | 3.000 | 2.000 | 0.375 | 0.875 | 3.625 | 3.625 | 4.625 | 0.531 | 1.750 | 3.500 | 0.688 | 5.000 | 85,000 | 6,500 |

| 2198A | K-2 | 6.000 | 1.562 | 2.750 | 2.250 | 0.500 | 0.865 | 4.420 | 4.200 | 5.625 | 0.562 | 2.750 | 3.000 | N/A | 4.500 | 104,210 | 12,330 |

| WS4103PSS | F-2A Spec. | 3.075 | 1.375 | 1.218 | 1.500 | 0.250 | 0.750 | 3.000 | 2.750 | 4.750 | 0.531 | 2.000 | 2.219 | N/A | 2.063 | 28,000 | 2,800 |